ccording to the U.S.

Environmental Protection

Agency, the United States produced 254 million

tons of municipal solid waste in 2013. And

though 87 million tons of that material from

landfills was diverted through recycling and composting,

what if the nation could do better? What if landfills could

become local sources of clean energy production? Better

yet, what if all waste streams, like those from agricultural,

livestock, and food production, could essentially become

fuel refineries at a local level?

It’s a question being asked by a collaboration of national

laboratory researchers who want to create energy conversion

technologies designed to mine the carbon out of waste

processes that traditionally have been an environmental

burden to the planet and a disposal headache for humans.

“The idea of using waste as energy source really isn’t new,”

said Cynthia Jenks, assistant director of Scientific Planning

and division director for Chemical and Biological Sciences

for Ames Laboratory. “For example, some municipal and

regional utilities already burn landfill waste as a source

for electrical power. But we think there are better, cleaner

and more efficient ways to get at that carbon and use the

potential energy from it.”

A new concept was born of the Big Ideas Summit, held

by the Department of Energy and its national laboratories

in 2015. The effort, being co-led by Ames Laboratory and

Pacific Northwest National Laboratory, is a collaboration of

12 national laboratories to find new catalytic technologies

that can efficiently produce biofuel from waste streams.

The goals are specific. Make the technology as simple

as possible, yet adaptable to diverse waste streams. Locate

it right at the waste stream source, whether it’s a landfill,

livestock farm or commercial facility. Make it easy and

economical to produce and deliver through the use of

modular manufacturing.

“The idea brings together a lot of overlapping interests:

chemical research, applied engineering, modular

manufacturing, waste management, agriculture, industry,

A

What if America’s next big fuel source is its trash?

B Y L A U R A M I L L S A P S

Waste Stream to

Energy Source:

“That’s really the‘big idea,’”said Jenks.

“Where there is waste, there is energy.”

Inqui r y I s sue

2

| 201 5

17

16

Inquir y Is sue

2

| 201 5

and energy-sector investors. It’s a complex idea with a lot of

moving parts, but one that we think will get us a lot closer to

accessing the potential energy in these underused resources,

and a lot closer to the nation’s sustainable energy production

goals,” said Jenks.

To meet the goal, the participating national laboratories

will pool their skills in materials and chemical sciences,

high-performance computing, engineering, and applied

technology. Ames Laboratory will lend its expertise in

catalysis to the project through its Chemical and Biological

Sciences Division. Scientists Igor Slowing and Aaron Sadow

have already done extensive work in creating catalysts that

are able to convert carbons, by placing catalytic agents on

high-surface-area nanomaterials. They want to develop

processes that make possible the controlled decomposition

of waste polymers into useful hydrocarbons.

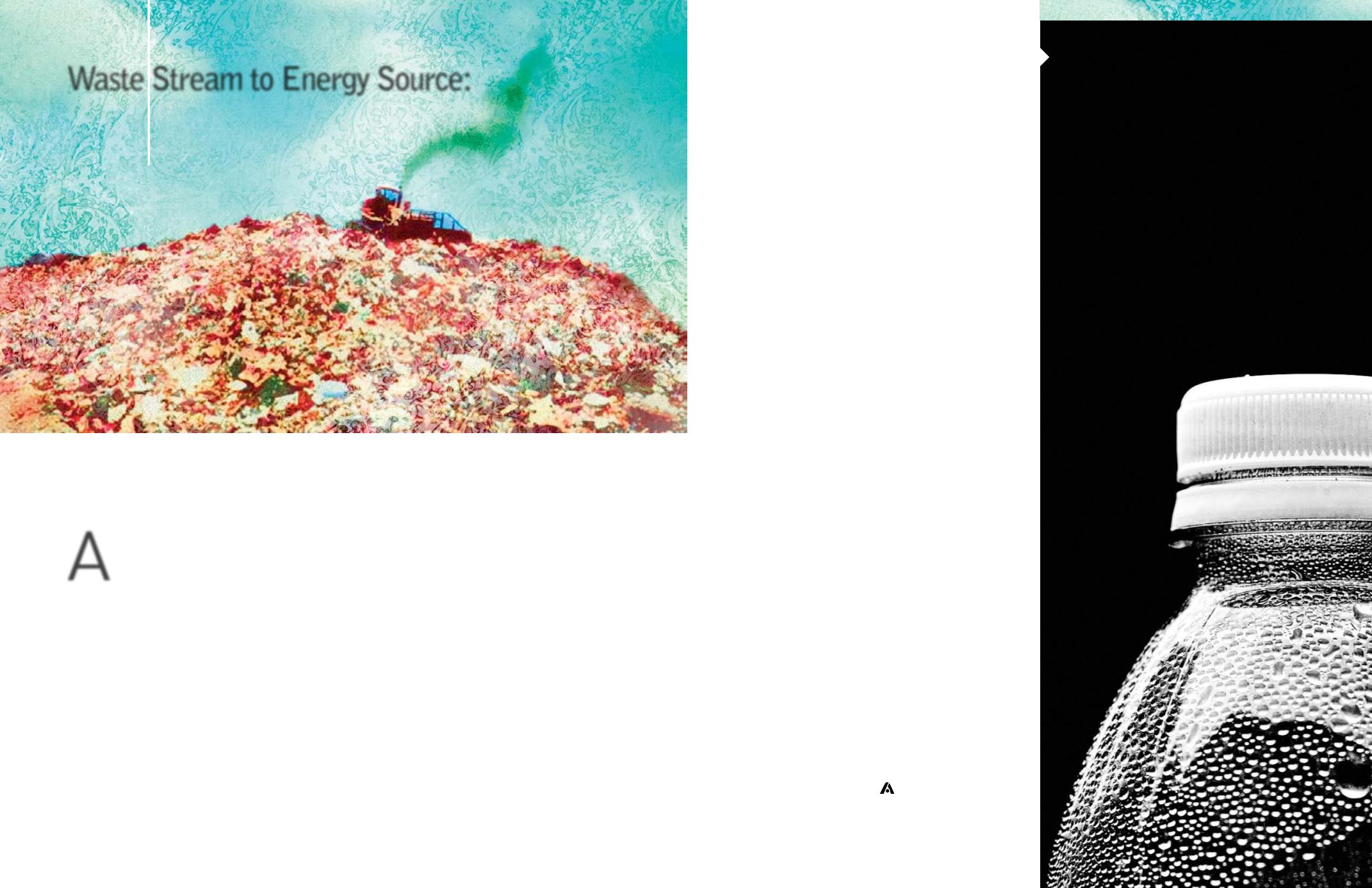

“A large amount of the waste that goes into landfills

is polymers…plastics. These are very carbon rich, very

processed materials, and if we were to be able to convert

that waste into new, useful compounds or energy, that

would make much better use of them,” said Sadow. “Right

now, we’re wasting all that carbon. It’s just sitting there in

the trash.”

Sadow and Slowing will also be applying similar techniques

to the conversion of wet sludge and agricultural wastes.

Sadow said the scientific challenges are complex, with

a need for chemical reactions that can be highly efficient,

operating at low temperature and low pressure. They will

also need to be capable of adapting to changes in the raw

material feeding them.

“Any waste stream is verymixed, and its composition varies

over time,” said Sadow. “We can physically sort and then

convert, but then there’s that separation step. We don’t really

know how to chemically convert mixtures in general. That is

a really big, interesting, fundamental challenge that research

hasn’t yet tackled, and that’s exciting to contemplate.”

While the group estimates that these localized biofuel

refineries would produce small quantities of biofuel—an

average of the equivalent of 125 barrels of oil per day—the

collective impact could be staggering. Transforming the

available national waste streams into fuels and other useful

chemical products could translate to the equivalent of 2.7

billion barrels of oil per year, or 40 percent of the nation’s

annual crude oil use.

“That’s really the ‘big idea,’ ” said Jenks. “Where there

is waste, there is energy. We believe that the collective

expertise of the national labs, including the chemical

research strengths of Ames Laboratory, puts that big idea

within reach.”

“A large amount of the waste that goes

into landfills is polymers…plastics.

These are very carbon rich, very

processed materials, and if we were to

be able to convert that waste into new,

useful compounds or energy, that would

make much better use of them. Right

now,we’re wasting all that carbon. It’s

just sitting there in the trash.”

Aaron Sadow