Ames Laboratory’s LENS system creates complex, 3D shapes by depositing metal

powders through the nozzles and simultaneously melting them with a laser.

12

Inquir y I s sue 2 | 2016

Inqui ry I s sue 2

|

2016

13

dditive manufacturing, also known as 3D

printing, has reached a widespread measure

of success in manufacturing processes using

polymers, or plastics. But the use of metal alloys

for additive manufacturing has lagged due to lack of both

materials and process development.

Ames Laboratory and Oak Ridge National Laboratory

have been awarded $5 million from the U.S. Department of

Energy’sAdvancedManufacturing Office (AMO) to improve

the production and composition of metal alloy powders used

in additive manufacturing.

“There’s a lot of intense interest focused on additive

manufacturing with metal alloys, because there are so many

potential applications,” said Iver Anderson, project leader

and senior metallurgist at Ames Laboratory and adjunct

professor of Materials Science and Engineering at Iowa

State University. “Industry has demands for prototyping

parts, design development, reducing waste of expensive

materials, and efficiently producing custom and legacy

components for their customers.”

Because additive manufacturing uses metal alloy powders

as its raw material, the ability to control the properties and

quality of those powders becomes paramount to the quality

of the final product, and achieving properties equal to cast

and machined or, especially, cast/forged and machined parts.

The project will improve powder production by developing

advancesinahigh-pressuregasatomizationprocesspioneered

at Ames Laboratory and will design and customize alloys

specifically for additive manufacturing processing methods.

Modeling and simulation of gas atomization process stages at

Ames Laboratory will use a flow simulation code developed

by the National Energy Technology Laboratory for part of

the work. The experimental gas atomization work and alloy

design calculations/verification also will be performed in

the powder synthesis facilities at Ames Laboratory. Oak

Ridge National Laboratory’s Manufacturing Demonstration

Facility (ORNL-MDF) will conduct the corresponding

additive manufacturing experiments.

“Today, if a manufacturer went to metal powder producers

with a shopping list of the alloys and powder specifications

they needed for their manufacturing process, they very

likely wouldn’t find what they want,” said Anderson. “The

customization capabilities are just not there, and we need

to get there. That is going to be the key to commercially

competitive additive manufacturing processes.”

B Y L A U R A M I L L S A P S

A

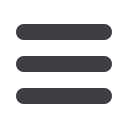

A micrograph shows the perfectly spherical shape of powder

particles formed by high-pressure gas atomization (HPGA).

Better Powders

AdvanceAdditive

Manufacturing

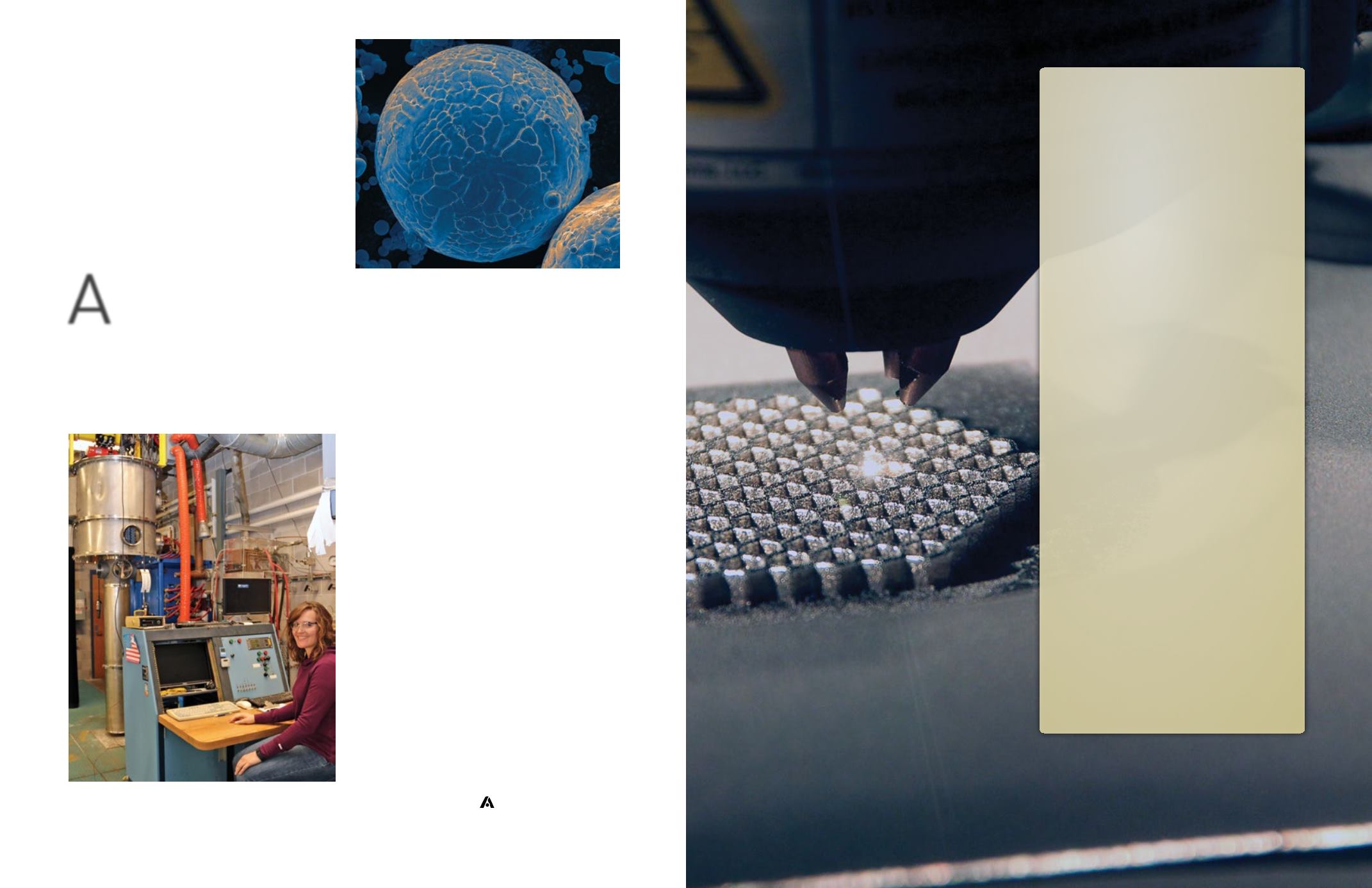

Ames Laboratory scientist Emma White sits at the control

panel for one of Ames Laboratory’s HPGA systems.

In a separate, but somewhat related project,

a group of Ames Laboratory researchers will be

working to characterize what happens to metal

powders as they are processed into shapes through

3D printing processes. The goal is to be able to fine-

tune the 3D printing process on the fly to maximize

the properties desired for the particular piece being

manufactured.

Ames Laboratory scientists Ryan Ott, Pete

Collins and Matt Kramer will be working with

colleagues at the Stanford National Accelerator

Laboratory (SLAC) and Lawrence Livermore

National Laboratory (LLNL) to develop both

hardware and software to characterize the powders

in situ

as the advanced manufacturing process

builds up complex shapes layer-by-layer.

“We’ll look at analyzing powders in two types of

systems, both powder feed and powder bed,” said

Kramer, who is also Ames Laboratory’s Materials

Science and Engineering program director. “Powder

feed is like our LENS (laser engineered net

shaping) system where powders are delivered via a

nozzle and melted in place by a laser. Powder bed

spreads a thin layer of the metal powders over the

entire surface and a laser then melts only a portion

of the powders in the particular shape needed.”

The Ames Laboratory team is characterizing the

commercial powders and developing the power feed

system that can be used with the beam line at SLAC

to analyze the powders as they are built up layer by

layer via X-ray tomography and diffraction. LLNL

is developing the powder bed system and high-

speed imaging and thermal diagnostics. According

to Kramer, the project will evaluate a wide range

of commercial powders, including a titanium-

aluminum-vanadium alloy commonly used in the

aerospace industry. Funding for the project will

come from DOE’s Advanced Manufacturing Office

with Ames Lab receiving roughly $1.2 million of

the approximately $4 million project.

Characterizing powders on the fly