22

Inqui r y I s sue

1

| 2016

Inqui r y I s sue

1

| 2016

23

ature provides myriad examples of unique

materials and structures developed for specialized

applications or adaptations. An interdisciplinary

group of researchers at Ames Laboratory is trying to

unlock the secrets that organisms use to build such complex

structures so that power can be used to create materials not

found in nature and not capable of being synthesized by

conventional means.

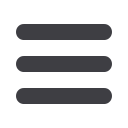

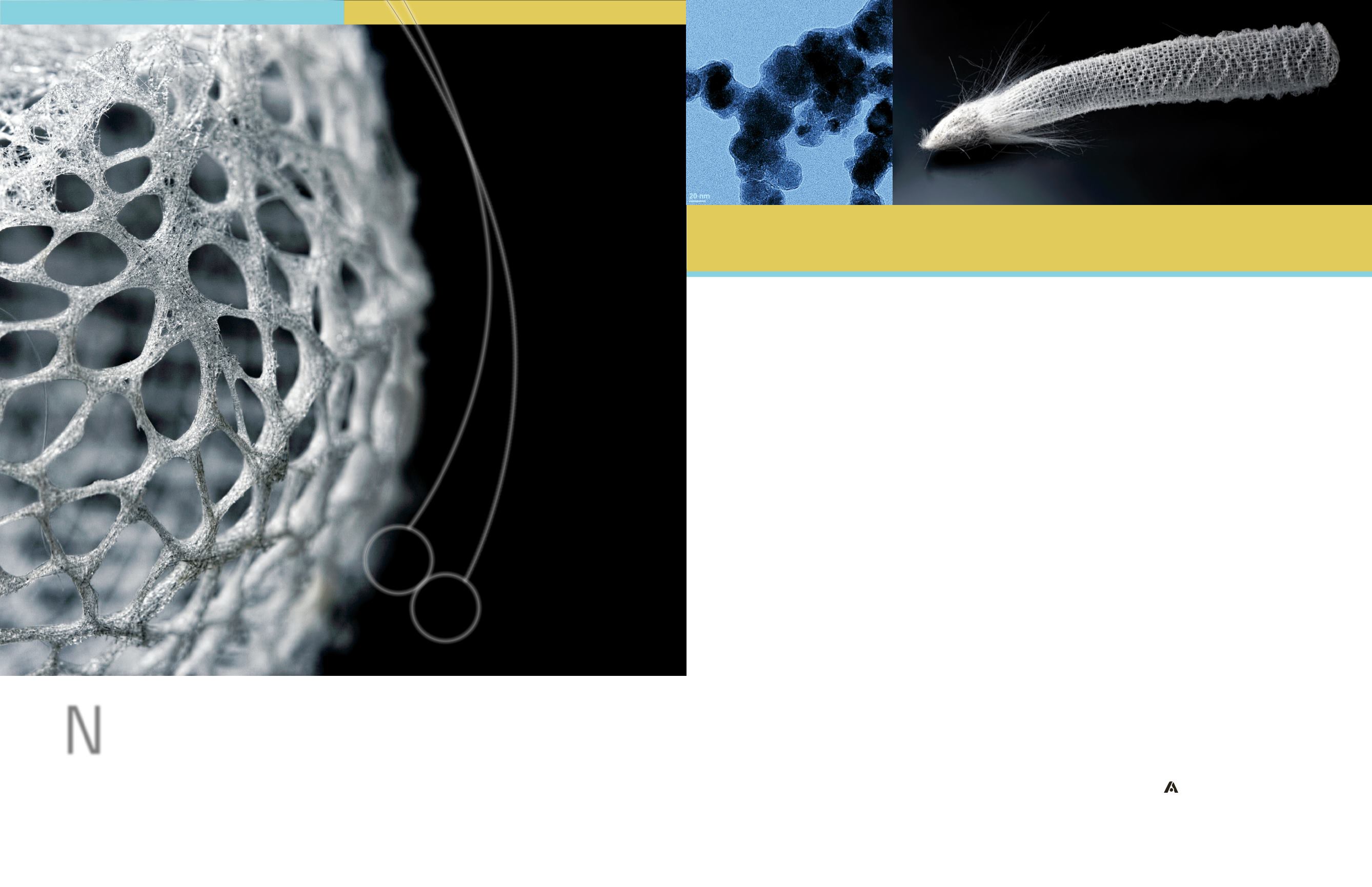

“Naturehas lotsof examplesof thesehierarchical structures

and they’re usually organic-inorganic composite materials,”

said Surya Mallapragada, Ames Laboratory scientist and

Iowa State University Carol Vohs Johnson Chair in Chemical

and Biological Engineering. “A glass sea sponge skeleton is

a perfect example of these structures that are templated by

the organic phase. You have inorganic nanocrystals that form

and it’s a multiscale assembly process, which in most cases

happens at mild temperatures and conditions, such as pH.”

“So we look to nature for inspiration and as a source of

bio-molecules to see how we can recreate some of those

processes that create these wonderful materials with

hierarchical assemblies or uniform structure,” she said.

So far, Mallapragada’s team has been able to replicate the

creation of magnetite by studying magnetotactic bacteria.

These bacteria form magnetic nanocrystals or chains of

nanocrystals that they use to orient themselves with the

Earth’s magnetic field. Using self-assembling polymer

templates and proteins from the bacteria, researchers were

able to grow magnetite crystals.

“We’ve used this approach successfully to grow magnetite

nanocrystals,” Mallapragada said, “but we’ve gone beyond

that, using these techniques to create cobalt ferrite and other

magnetic nanocrystals that are not found in nature. That’s a

great example of templated synthesis.”

The group has also worked with calcium phosphate to try

to mimic the light-weight strength found in bones.

“In some case, we need to come up with synthetic

analogs which can do the same job, but are more robust,”

Mallapragada said. “In many cases, the biomolecules aren’t

as robust. Proteins are fragile molecules so if we can do it

with synthetic polymers, that gives us a lot more flexibility.”

It’s one thing to create nanocrystals. Getting those

nanocrystals to then organize and form microstructures and

then macro-scale structures is something altogether different.

“They’re not at the level of complexity we see in nature

—that’s the Holy Grail,” Mallapragada explained, “but

that’s the inspiration and we’re trying to get there with

synthetic approaches.”

The latest goal for harnessing this natural building process

is the creation of metamaterials, so-called left-handed

materials, that have interesting optical properties that don’t

occur in nature.

“We’re looking at using organic templates to assemble

inorganic particles to get the desired properties,”

Mallapragada. “We have a very strong collaboration with

Ames Laboratory physicists Costas Soukoulis and Thomas

Koschny, and they’ve done some wonderful work with

simulations and predictions of structures and developed

some lithographic structures, but those are only 2D. So it’s

really a perfect case for using these bioinspired approaches

to self-assemble these metamaterials into 3D structures.”

Mallapragada again points to the glass sea sponge for

the type of multiscale assembly that’s required to build 3D

metamaterials.

“The sea sponge has order on multiple scales—nanoscale,

micron-scale, millimeter-scale. It’s a multi-scale assembly—

it looks like the Eiffel tower—and that’s why it has a very

great strength to weight ratio,” she said. “So we need a similar

hierarchy. Define the shapes at nanoscale, but then have an

ordered arrangement of these nanoscale objects in 2D and

then 3D to get the desired properties.”

In addition to using self-assembling polymers, which

provide long-range order, DNA has also been used because

it allows for specificity in the placement of nanoparticles.

To create metamaterials, the team is looking at using both

to control the placement of gold nanoparticles in a specific

pattern, build up layers and then apply a gold film coating to

the entire structure to acquire the desired properties.

“It takes a very interdisciplinary approach,” Mallapragada

said. “We have molecular biologists (Marit Nilsen-Hamilton)

for the DNA side, materials chemists (Mallapragada) for the

polymer synthesis, Soukoulis and Koschny for the theoretical

prediction of the structures and (physicist) Alex Travesset for

modeling the kinds of structures can we get.”

“We need good characterization so David Vaknin is

looking at scattering methods and Tanya Prozorov has

been doing transmission electron microscopy work,” she

continued. “Andy Hillier (chemical/biological engineer) has

been involved in metallization, applying the continuous film

of gold on those nano structured templates. So it’s a multi-

level, multi-step, multi-component synthetic process.”

Mother Nature should be flattered!

N

M

aterials:

B

ioinspired

B Y K E R R Y G I B S O N

BORROWING FROM NATURE’S PLAYBOOK

Opposite and top right

: A glass sea sponge skeleton showing the complex nature of its structure which provides amazing

strength. (Photos by Michael Monn, Kesari Lab, Brown University.*)

Top left

: A micrograph of magnetic nanocrystals grown

by Surya Mallapragada’s research group.

*New functional insights into the internal architecture of the laminated anchor spicules of Euplectella aspergillum, PNAS,

www.pnas.org/cgi/doi/10.1073/pnas.1415502112