6

Inqui r y I s sue

1

| 2016

Inqui r y I s sue

1

| 2016

7

LIKE SANDTHROUGH AN HOURGLASS

Iver Anderson and Emma White, metallurgists at Ames

Laboratory, like to show off samples of metal powders

encapsulated in custom-made hourglasses to visitors. Dull

gray, the powders are barely remarkable in and of themselves,

let alone in comparison to each other.

Until the hourglasses are flipped and observers can compare

how the powders flow through the narrow necks of glass. The

powder created by traditional manufacturing methods doesn’t

flow, exactly. It starts and trickles and stops. It needs shaking

and manipulating to get through. The other powder, produced

at the Laboratory’s high-pressure gas atomization facility,

pulses smoothly through the hourglass of its own accord.

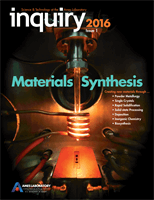

It’s all because of the smooth

spherical particles produced by Ames

Laboratory’s gas atomization method,

an improvement over traditionally

manufactured powders.

“You can see they’re chunky,

randomly sized, with rough edges,”

said White of the traditionally-made

powder particles, comparing scanning

electron microscope images of the

two. “They don’t flow past each

other, and that’s going to require a pulsing mechanism or an

agitator in the manufacturing process. That’s going to cost

the manufacturer more in energy to

run their production line.”

It’s only one of the many benefits of

powders created by the gas atomization

process, which has garnered the

Laboratory at least 16 patents over

the last two decades. It also helped

create spin-off company Iowa Powder

Atomization Technologies, which

was recently acquired by Praxair, and

exclusively licenses Ames Laboratory’s

titanium atomization patents to introduce titanium powder

to an eager marketplace.

SPLITTING LIQUID INTO DROPLETS

Gas atomization is a powder production method that

uses high-pressure gas flow to distintegrate molten metal

into particles. In the Metals Development building at Ames

Laboratory, Anderson, a senior metallurgist, and White, a

post-doctoral researcher, are able to produce experimental

quantities of powder with the Laboratory’s experimental

apparatus, about half of a liter volume per production run.

Another, larger gas-atomizer at Iowa State University’s

Applied Sciences Complex can produce around three liters.

The basic operation is the same in both. Metal is melted

by an induction furnace and held in a crucible with a

stoppered opening in the bottom. When the stopper is lifted,

the metal flows through a specially designed pour tube into

an atomization nozzle (also unique to Ames Laboratory)

that focuses a number of round-hole gas jets on the molten

metal in a tight pattern. The individual jets of gas—argon,

nitrogen, or helium depending on the run—knit together

to form a supersonic “curtain” that flows directly across the

liquid metal flow and forces the melt to couple directly with

the high kinetic energy of the supersonic gas, creating a

controlled droplet spray.

“This energetic coupling happens because the gas curtain

creates a suction that pulls the melt into the atomization

zone and simultaneously forces an upward directed gas

counter-flow to form that splits the liquid as though there

was an umbrella stuck underneath it and makes it flow

sideways, across to the outer edge of that round nozzle,”

said Anderson, who is also an Iowa State University adjunct

professor of materials science and engineering. “So it gets

presented to the gas as a thin film that is forced by the gas to

turn in the gas flow direction so it can shear past the surface

of that film, and strip off waves of liquid that break at their

crest to form droplets.

“It’s the same phenomenon you can see on the surface of a

pond hit with a gust of wind. You see small ripples and a spray

of water come off that gust.”

Once the droplets form, they solidify rapidly as they fall

through the spray chamber and are cooled by additional gas

halos. The resulting powder particles are separated from the

combined gas flow and settle into two powder collector cans

that are connected to the end of the spray chamber. The

cleaned inert process gas exits through two types of final filter

devices and is exhausted from the lab.

ADVANTAGES

Ames Laboratory’s gas atomization method produces

powders that are customizable, consistently sized and

smoothly spherical. The advantages of a perfectly formed

powder aremultiple. Besides the advantage of smooth powder

flow already mentioned, the individual round particles have

little internal porosity and pack together optimally in bulk.

Both qualities reduce dead air space and improve the quality

of parts produced using these powders.

Using gas atomization, Ames Laboratory has produced

powders of iron, aluminum, nickel, copper, tin, magnesium

and various other metals and alloys, in addition to titanium,

one of its key research accomplishments.

“The titanium industry is extremely interested in powder

metallurgy and final-shape consolidation methods,” said White.

“Titanium is expensive and the large amount of titanium

waste produced during machining cast parts into final shapes

significantly increases their costs. They see advances in powder

metallurgy as an effective cost control strategy by making parts

into near-final shapes and minimizing waste titanium.”

The powders produced by this method have also been

used in the production of stronger alnico (aluminum, nickel,

cobalt, and iron) permanent magnets, and in the production

of an experimental power transmission cable fabricated out

of an aluminum and calcium composite.

And the possibilities of these metal powders don’t just

look to the future, but may also redeem materials from the

past that had been abandoned by researchers and industry as

impossible to work with.

“You can create an alloy with fantastic properties, but if you

can’t make something useful out of it, it will never get off the

lab bench. This method enables us to revisit materials that

have been around a long time, give them a second chance,

and find new potential applications for them,” said Anderson.

IMPOSSIBLE SHAPES OUT OF INCREDIBLE ALLOYS

Ames Laboratory is seeking to expand its powder

production capabilities beyond research capacity, with the

goal of being able to produce up to 200 pounds of powder in

one production run.

At that scale, new opportunities for research are possible,

explained Anderson and White. Large batches provide

sufficient samples amounts for shared research projects

among multiple national laboratories and industry partners.

With new 3D printing and additive manufacturing

capabilities expanding rapidly, Ames Laboratory will be able

to position itself as a provider of custom metal powders for

these research areas, continuing to fine-tune the abilities of

the gas atomization process.

All of this is a natural progression of the research goals

Anderson has worked toward for decades.

“The ability to make impossible shapes out of incredible

alloys is my mission in life. I want to work on ways to get this

done,” Anderson said.

B Y L A U R A M I L L S A P S

Perfect Powder:

AMES LABORATORY’S PROCESSES PERFECT METAL POWDERS FOR MANUFACTURING

High-pressure gas atomized metal powders at various levels of magnification showing the perfection of the spherical end product.

Iver Anderson

Emma White

“You can create an alloy with fantastic properties, but if you can’t make something useful out of it, it

will never get off the lab bench.This method enables us to revisit materials that have been around a long

time, give them a second chance, and find new potential applications for them.”